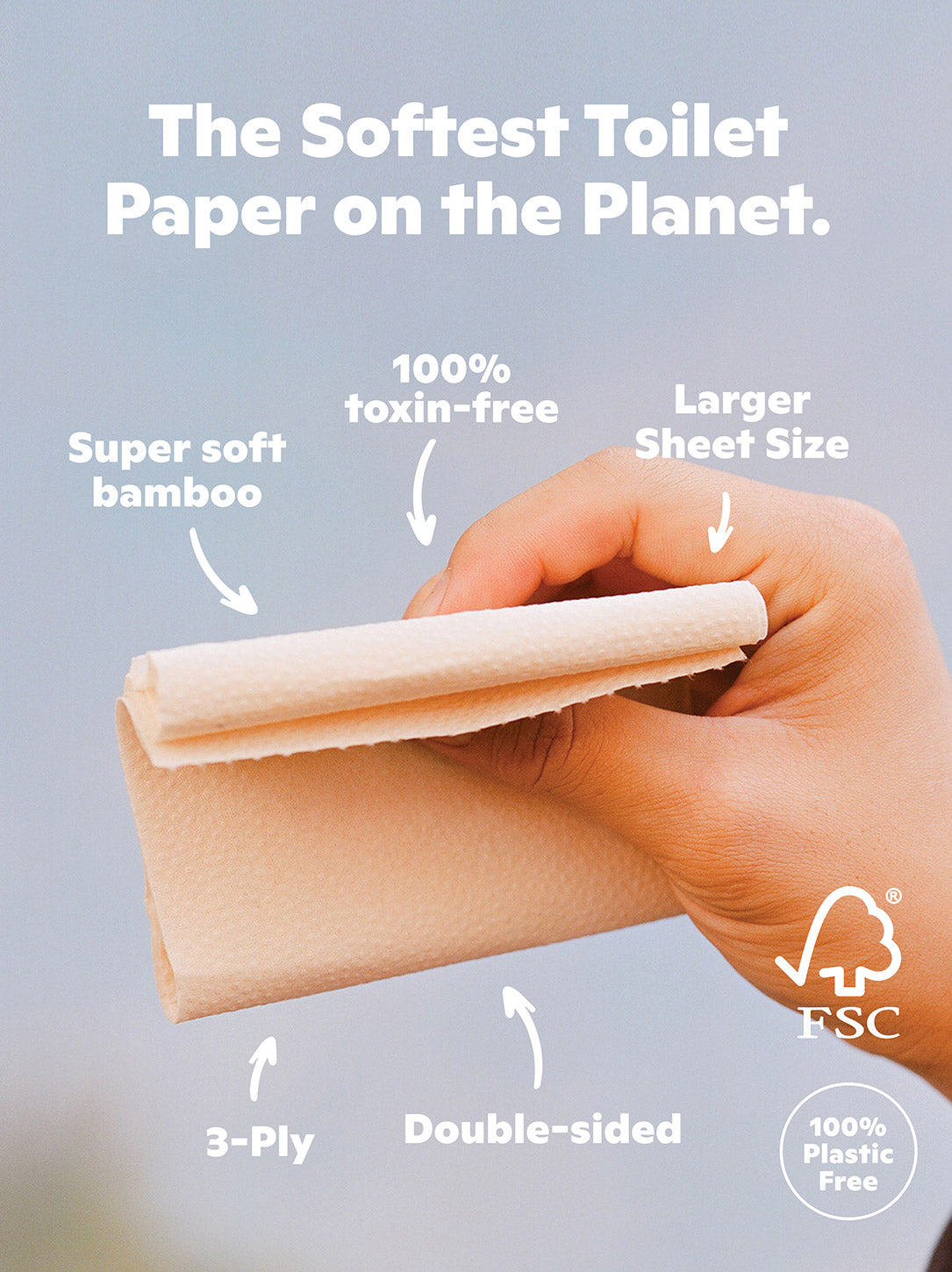

Made from silky soft FSC® Certified bamboo.

Delivered in 100% plastic-free packaging.

Currently, all the bamboo pulp produced worldwide originates in China. That’s because bamboo grows abundantly there, and the infrastructure to process it is well-established.

Life cycle analyses comparing the impact of tree-free toilet paper produced in China and sold in North America to that of conventional tree paper brands indicate that, even with the incremental carbon and environmental costs associated with ocean freight, tree-free paper results in less carbon emissions by a factor of three.

How can that be? Because tree paper relies on fiber harvested from the boreal forest, the most efficient system of carbon capture on earth and a crucial line of defense against climate change. The benefits of keeping those forests working as they’re supposed to far outweigh the costs of the alternative.

While we’re on the topic, most “American” toilet paper isn’t actually made in America per se. The majority of the pulp now comes from carbon-intensive eucalyptus plantations in Brazil. These plantations stand where rainforests once thrived only a generation ago, with devastating impacts on wildlife, biodiversity, water supply, and global warming. Go ahead, check the package on your grocery store TP. More likely than not, it says “Made in the US with imported parts or materials.” Toilet paper hasn’t been made from American trees in generations.

There are six main PFAS compounds that account for the majority of PFAS that is detected in toilet paper and other household products—PFHxA, PFOA, PFDA, 6:2 diPAP, 6:2/8:2 diPAP, and 8:2 diPAP. We tested for all six of these, in addition to 22 additional compounds, which are far less prevalent. We tested PlantPaper for all 28 of these, and had zero detections.

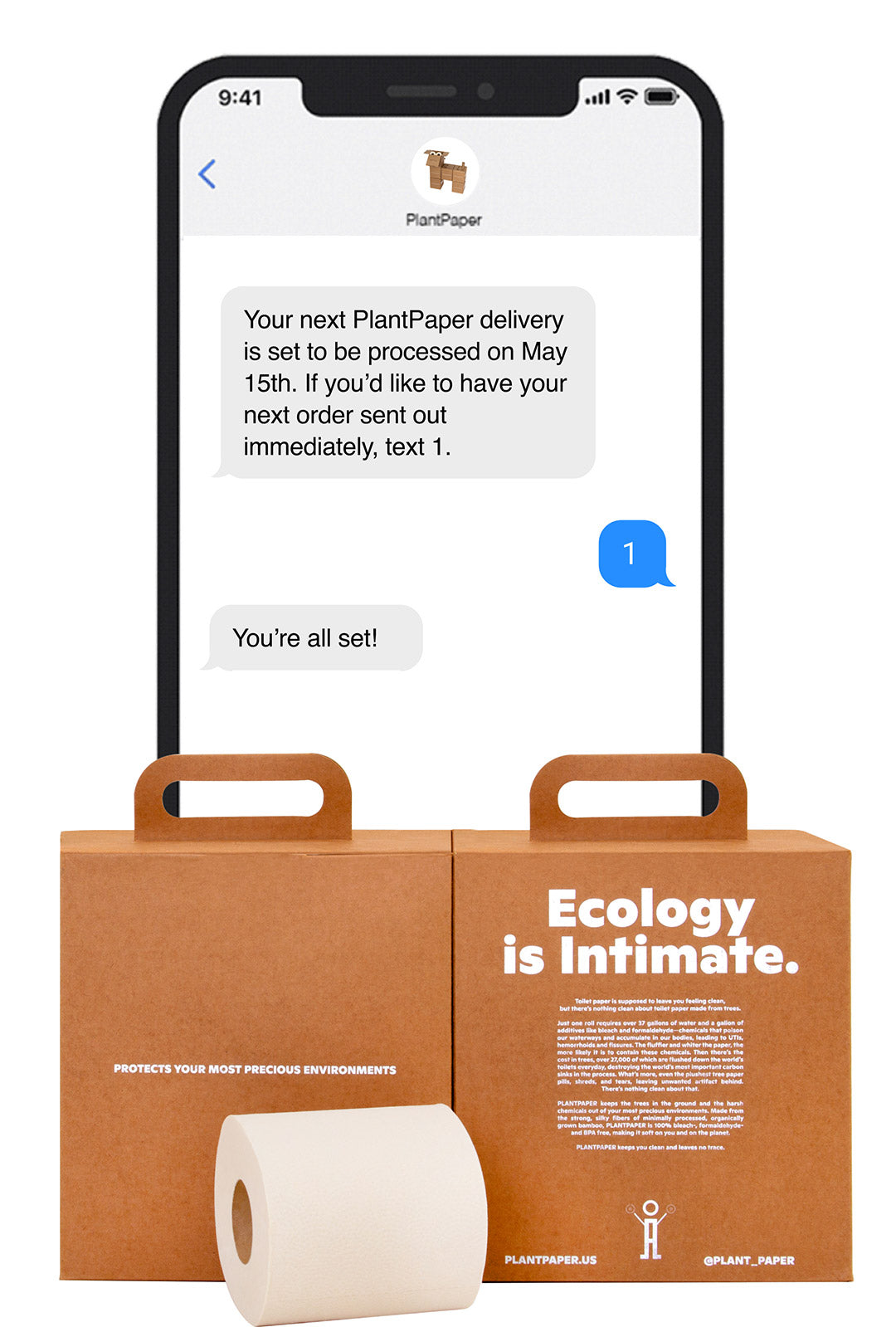

We like to think of this as a very fractional cost over the course of a year to reduce harmful chemicals on your body and save old growth trees and forests, our stalwart against climate change. PlantPaper on average is about .20 cents more than comparable tree-based brands. The average person uses around 70 rolls per year, so that means the yearly cost is only around $15 more to make the switch to PlantPaper.

You bet! PlantPaper breaks down easily in septic systems. To see for yourself, try this test at home:

1. Put 4 squares of PlantPaper in a glass jar.

2. Fill the jar ¾ full.

3. Put back on the lid and shake heavily for 10 seconds.

4. If the paper has broken down into small pieces (it will!), then it’s septic-safe.

Compared to other 2- and 3-ply premium toilet paper brands, whether tree- or bamboo-based, PlantPaper breaks down quickly and completely.

Yes, PlantPaper is 100% free of bleach and formaldehyde.

Until recently, almost all toilet paper was made with chlorinated bleach, which, when combined with organic substances like tree pulp, produces dioxins, a class of highly toxic compound considered a “persistent organic pollutant” because of how difficult they are to eradicate. In the last few years, as the damaging effects of bleach on our bodies and the environment became harder to ignore, paper mills in North America have largely switched to an ECF (Elemental Chlorine Free) process. This is an improvement over earlier methods, but numerous studies have confirmed that ECF bleaching still results in the formation of dioxins. That’s why we chose to make PlantPaper with zero bleach of any kind.

Studies suggest that some toilet paper products may contain formaldehyde. PlantPaper is lab-tested 100% free of formaldehyde.

Directed and narrated by Bonnie Wright

Sound on!

Old growth forests are complex ecosystems that develop over the course of centuries or millenia. Once cut down, they never regain their capacity for carbon storage or their ability to sustain wildlife.

Chemicals used in the bleaching process can combine with compounds in the environment to form dioxins and furans—persistent organic pollutants.